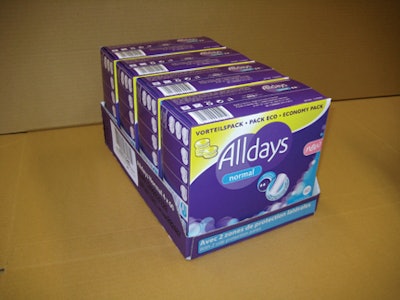

Procter & Gamble has launched a newly designed shelf-ready package for primary packages of Alldays and Always feminine care products. As a replacement for a more traditional corrugated RSC, the new tray and hood costs less, performs better, and racks up some impressive gains both in efficiency and in sustainability. Consider:

• Factoring in both material cost savings and better transport efficiency, the new format costs about 20 cents less per unit.

• 80% less ink is involved

• 28% less corrugated is used

• Handling by in-store personnel is greatly simplified

• On-shelf appearance is much better

“The perforated SRP was never an optimal package because it was an adaptation,” says Ibrahim Ulas, section head at P&G’s Feminine Care Package Development Group in Schwalbach, Germany. “An existing case was modified to meet a new set of shelf-ready requirements. When the whole SRP trend was new, the adaptation was acceptable enough. But those early days of SRP are over, and these days we want a much more optimized packaging format.”

The old SRP came “pre-made” in the sense that it was a knocked-down blank with a manufacturer’s joint. The new SRP consists of two flat pieces of single-wall corrugated, neither of which has a manufacturers joint. One piece is formed into a tray that holds four, eight, or twelve primary packages. The other piece is a hood that fits over the primary packs in their tray. Only the tray is printed.

A number of shortcomings have been addressed by this new format. First, in-store handling is much easier. A simple glue point attaches the hood to the tray. All the store workers need do is break this bond with the bare hand, lift the hood from the tray, and place the tray out on the store shelf. Ulas estimates the time required to make the new SRP shelf-ready has been cut in half. Furthermore, it’s a lot easier for a store worker to quickly spot the specific SKU he’s looking for when he goes to the back room for a fresh SRP because now most of the primary package’s graphics show through the unprinted hood.

“When you think about how important it is for our trade partners to keep their labor costs in check, you realize how valuable this new SRP is to them,” says Ulas.

Second, the finished appearance of the old SRP left a lot to be desired. Store personnel with multiple responsibilities and little time to spend on any one of them rarely were able to carefully tear along the perforation lines of the old case. Consequently, cases often looked torn or ragged. Ulas describes this as a “First Moment of Truth limitation,” a reference to the phrase used by marketers to describe that all-important moment where a brand is supposed to beckon to the consumer. With the tray and hood format, the First Moment of Truth is no longer compromised by the sight of ragged bits of corrugated.

A third shortcoming addressed by the new SRP format centers on product visibility. The old SRP had either a high rim or a U-shape front panel that hid a whole lot of the primary packages. The new SRP delivers much better visibility of primary packs so that consumers can find in an instant the product variant they want.

A fourth advantage gained by switching to the new SRP format is made clear by the photo on this page. When it comes time for store personnel to discard of the package, much less packaging material is involved.

While Ulas isn’t in a position to identify the packaging equipment involved in this project, he does say that it is considerably more flexible and easier to change over than the case packer used for the old SRP. So that’s one more benefit gained since the switch was made.

The first tray-plus-hood SRPs went into production at P&G’s Crailsheim, Germany, plant in January 2009, says Ulas. Other plants in Western Europe will soon follow.