“This is exactly what consumers have wanted,” says Tim Lesmeister, vice president, marketing, WD-40 Company. “Millions love WD-40, but we’ve learned that more than 80 percent of WD-40 users have lost the straw at some point. We’ve solved that problem by literally giving consumers the ‘last straw’ with the WD-40 Smart Straw.”

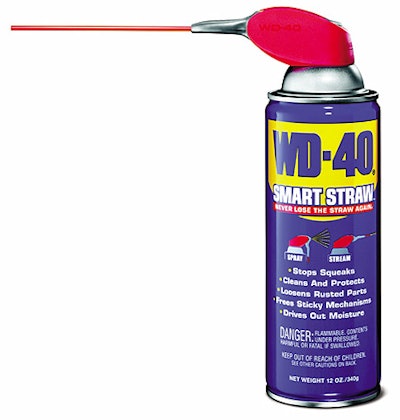

The Smart Straw has a standard aerosol valve with an actuator piece that uses a plastic extender tube (straw) that can be tilted to spray in two ways. When the straw is in the down position, it sprays through the actuator and delivers a regular spray, to cover a larger surface area. Tilted up at a 90º angle (as shown), the straw allows the WD-40 to be expelled through the straw for more precise application. Made of polypropylene, the straw is permanently attached to the actuator part. Manufactured by Mar-Lee Packaging & Consumer Products, the Smart Straw uses an insert in the actuator and a valve manufactured by Summit Packaging.

The 12-oz steel can is manufactured by Crown Holdings with minor modification on the neck finish to adapt the actuator piece. The unit is currently being filled and assembled at I-K-I Manufacturing, though WD-40 says it will be producing the unit at its other contract packagers’ plants in the near future. The 12-count corrugated shipper was also modified for the new format.

“The Smart Straw is very different from our standard actuator,” says Lesmeister. “It is not possible at the present time to utilize some of the automated packaging machines when we manufacture the Smart Straw cans. It slows down the production lines, and adds a bit more manual labor.”

Selling for $3.99 versus $2.99 before the straw, the new package began shipping to retailers in April and is available nationally at major home improvement, mass merchant and grocery retailers. “We’re excited about the positive response we have received from our initial product tests and from general consumer feedback,” says Lesmeister. —Rick Lingle