This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

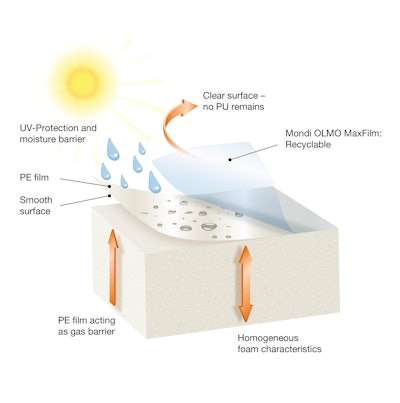

Mondi has helped its customers in the flexible foam industry to optimize their production and products with their peelable OLMO paper solution. With the new transparent OLMO MaxFilm even more chemicals and therefore costs can be saved. The film acts as a window to the foam, enabling a complete monitoring of the production process and allowing an immediate adjustment of the production parameters and hence a better result of the foam quality. This leads to a substantial saving of the chemical TDI and reduced material loss. Furthermore, with a full coverage of the foam block on all four sides with Mondi’s OLMO MaxFilm, chemicals cannot evaporate and the foam block is protected from UV light, moisture as well as reactive chemicals. In addition, the entire production process is cleaner as the machine conveyors are shielded from sticky foam and the workers profit of a reduced toxic vapour exposure.

OLMO MaxFilm is the strongest peelable process liner available on the market. Due to the peelability, the liner remains free of contaminants and is therefore recyclable. “The new material not only complies with our zero waste concept, but also results in a closed loop recycling system”, Jussi Vanhanen, CEO Mondi Fibre Packaging, proudly explains. “OLMO MaxFilm is designed to run on all machine types and supports an increased foam output of our customers”, Ola Forsberg, Industry Group Manager Foam Paper states and continues, ”in addition, our OLMO MaxFilm has a low risk of webbreaks and due to its light weight, leads to more linear meters per reel which subsequently leads to less reel changes. All in all, an extremely efficient solution for more comfort.”

By using OLMO MaxFilm, the runnability can be improved significantly as the new solution comprises a more stable process liner with a lower risk of webbreaks. This also results in a better production safety for the employees thanks to the minimized contact with potentially toxic vapours. “We are happy to support our customers in the best possible way”, Vanhanen states and concludes, “and to help them save material, time and money – every day.”