Chances are you’ve heard of packaging take-back obligations and recovery fees, but only as a European phenomenon. That’s about to change. Beginning in late 2003 or early 2004, companies selling packaged goods in Ontario, Canada, will be required to register and pay packaging fees. A similar program will start in Quebec a few months later.

As a result of the Waste Diversion Act of 2002, producers are responsible for 50% of the cost of collecting and recycling the packaging and printed paper materials they place on the market in Ontario, with municipalities bearing the remaining 50%. A compliance organization called Stewardship Ontario (www.stewardshipontario.ca) will manage this obligation on behalf of industry, charging material-based fees to offset the recovery costs. This model is similar to the one used in most European countries and several Asian ones.

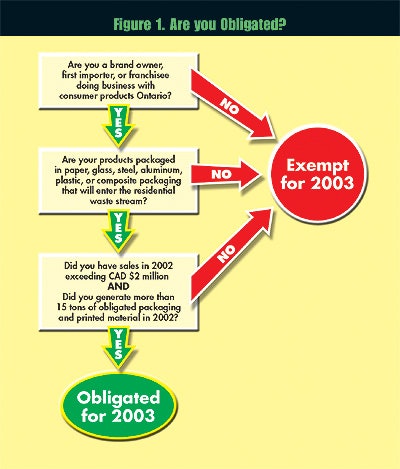

Are you obligated?

If you are a brand owner, first importer, or franchisee with Ontario sales in excess of CAD $2 million (US $1.4 million), you are obligated to pay fees on the “sales packaging” of products that are distributed to households in Ontario (“sales packaging” is nearly synonymous with “primary packaging;” it refers to packaging materials that go home with the consumer, as opposed to the corrugated shipper, for example, that stays in the store after its contents are displayed in a store aisle). However, you are exempt if the total weight of the sales packaging and printed paper is below 15 metric tons (see Fig. 1). As an alternative to paying fees into a collective recycling system, you can also manage an individual system for recycling the packaging and printed paper you put on the market.

Ontario’s regulations will require a shift in the way U.S. companies approach packaging compliance. Until now, packaging fees have only concerned corporations selling in Europe and Asia, most of whom have been able to delegate compliance with packaging fee requirements to their overseas subsidiaries. The regional headquarters or local sales offices report packaging data and sales figures to compliance organizations in each country and pay fees according to the total packaging material quantities. Often, these subsidiaries maintain detailed packaging databases to meet the reporting demands.

To comply with the Canadian requirements, any company that classifies as “obligated” must register with Stewardship Ontario by October 1, 2003, determine the amount of obligated packaging, report the material quantities placed on the market, and pay fees based on the total weight of each material (fees for each material are provided in Figure 2). This compliance process will entail gathering the necessary packaging, product, material type, and sales data to fulfill reporting requirements. In 2003, producers will be allowed to report estimated figures based on a data sample (representing 10 to 25% of their products) or using a “quick calculator” that Stewardship Ontario has developed based on sectoral averages. However, fees using the quick calculator are generally 50% to 100% higher than fees calculated using actual data. For 2004 and all subsequent years, full data will be required.

How much will this cost?

Figure 3 shows the 2003 fees on several sample packaged products and provides a comparison of these fees with those in Germany and France. If you plan to use the “quick calculator,” you can assume that your fees will range from about $1ꯠ per $1 million in wholesale sales for pharmaceuticals and OTC drugs to $2꼀/million for packaged food and $3꽤/million for cleaning and maintenance products. While reporting based on detailed data results in lower fees, the biggest challenge (and greatest cost) for companies with a wide range of packaging systems and SKUs will be in the data collection itself.

For companies whose product lines and packaging formats in North America closely match those in Europe or Asia, packaging databases maintained for existing reporting needs may be nearly sufficient for compliance in Ontario. However, companies will need to collect data on printed paper materials sold or distributed in Ontario—this includes informational inserts within the packaged product as well as sales brochures, catalogs and other promotional literature, bills and invoices, and magazines, none of which are covered in other programs. These materials are subject to fees regardless of whether they are sold or distributed free of charge.

Many packaging companies have criticized the fee structure, claiming that it favors certain materials. For example, the fee on a glass bottle is three times higher than for an equivalent PET bottle and the fee on a paperboard beverage wrap is about five times higher than the fee for plastic film wrap. Aluminum, in contrast, bears a negative fee, meaning companies that use aluminum will get a credit against their total fees.

In other countries with packaging fee systems, plastics and metals generally have much higher per-kilogram fees than paper and glass. MeadWestvaco stated in a letter to the Ontario Ministry of the Environment that “[a]doption of the Stewardship Ontario plan would make Ontario’s program one of the most discriminatory of all programs in the world as it relates to paperboard packaging. It effectively penalizes a packaging substrate that is derived from a renewable resource and has well demonstrated its recyclability and resource stewardship.”

This fee differential is not arbitrary. In fact, the Waste Diversion Act requires the fees to be derived from the actual net costs associated with recycling each material, which is a function of the collection and sorting costs and the value of the scrap material on the recycling market. Stewardship Ontario’s program plan includes a complex formula that attempts to adjust the various part of the formula to avoid penalizing materials that have achieved high recycling rates. However, since the Act only allows the inclusion of recycling program costs, the formula used to set the material fee levels does not take into account the disposal cost for the fraction of materials which are not recycled—in other words, the costs incurred by materials with low recycling rates are not fully reflected. This contributes to the discrepancy between the relative material fee levels in Ontario and those in other countries. Aluminum fees are calculated using the same formula, but since recycled aluminum commands a price higher than the costs of collecting and sorting it, the net “fee” is actually a credit. Aluminum fees do, however, include a proportional share of program overhead costs.

Under the current fee schedule, it is likely that the differences in fees may drive some manufacturers toward increased use of less recyclable materials, an unwanted side effect of the fee structure. Stewardship Ontario will set material fees each year based on the most recent recycling costs, and has projected that they will be required to double the amount of funding to support the program in five years, meaning that the fees will increase significantly. It is reportedly also examining the possibility of changes to the formula in future years.

How to comply

Once the program is approved companies will only have 90 days to report on their packaging materials. Therefore, they should prepare for compliance by doing the following:

• Determine whether they are obligated

• Designate someone to coordinate the company’s fulfillment of its new obligation

• Determine what packaging, printed paper, and sales data is available and what is needed

• Based on available data, decide whether the first year report will be based on full data, sample data, or the Quick Calculator

• Establish a plan to work with packaging supplier(s) to collect the data (full data will be needed for future years’ reports regardless of the calculation method used for 2003)

• Maintain an environmental packaging database

• Register with Stewardship Ontario

Victor Bell and Catherine Goodall are with Environmental Packaging International, a consultancy specializing in compliance with packaging and product stewardship requirements.