Early this year, printed circuit board manufacturer 3COM completed a switch to a new protective clamshell that incorporates electrostatic discharge (ESD) protection while it saves money and reduces packing time.

The Santa Clara, CA-based maker of communications electronics previously packed its printed circuit boards (PCBs) in an anti-static plastic bag. The bag was then loaded into a box lined with anti-static polyurethane foam cut to fit, a common packaging solution in the electronics field.

The new clamshell is thermoformed out of 15-mil Pentastat(TM) SC 8G/16 polyethylene terephthalate glycol (PETG)-modified sheet from Klockner Pentaplast (Gordonsville, VA). The sheet uses Eastar(TM) copolyester resin from Eastman Chemical (Kingsport, TN). It's thermoformed by Universal Protective Packaging (Mechanicsburg, PA), which also did the design work.

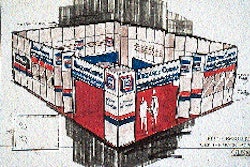

The hinged outer carton, made of 100% post-consumer recycled chipboard, is printed by Zellerbach (South San Francisco, CA). That company inserts the clamshells from Universal to supply 3COM with a complete package.

At 3COM, workers on the packaging line simply open the hinged box and inner clamshell. The self-locking clamshell is snapped shut, and the disk and manual are laid on top. The box is then closed and shrink wrapped.

Benefits of the new package include a healthy reduction in material costs over the previous package, although specific figures were not available. The savings did enable 3COM to move from four- to six-color box printing with no increase in overall packaging costs.

The packaging process went from three steps to one, since boxes arrive with the clamshells already inserted. That reduces handling and might even pave the way for an automatic board insertion process, an area which 3COM is investigating. Such automation wouldn't have been possible with the previous package. A final benefit is that the PETG clamshell is recyclable.

3COM selected Universal because of its prior experience with thermoformed ESD packaging. "We wanted a specialist, someone who knew all the special requirements of this application, where temperature fluctuations can destroy the ESD coating," says 3COM's Jim Kronik, purchasing section manager and part of the package design team.

Universal chose Klockner film for a variety of reasons. "When we designed the part, we recommended Pentaplast PETG film because Klockner had the highest quality, lowest-price certified-ESD material on the market," says Universal's Jim Breakey. "The consistency of the film also makes the package easy to run."

"We've had lots of positive feedback on the esthetics and functionality of the new package," says Kronik. "It's definitely meeting our requirements for reducing packing time and source reduction."