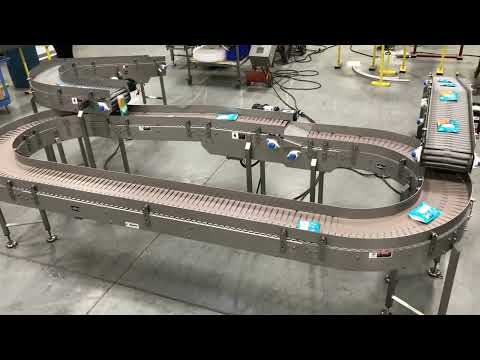

The infeed conveyor actually splits while product is suspended, held only by side grip belts, providing the gap necessary for a bottom label application.

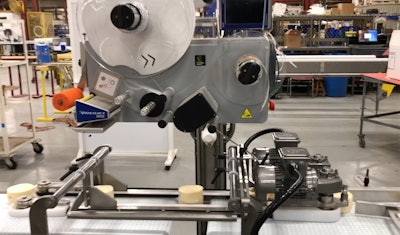

A customer supplied Videojet 9550 direct print and apply labeler with Intelligent Motion™ then applies the labels on top, bottom or both.

Downstream, a pneumatic reject pusher ejects imperfect labeled product for quality assurance using customer supplied label sensors.

Adjustable guiderails and PowerFlex motor controllers were mounted and wired to the conveyor. The motor on the left and the guiderails easily adjust for variable product widths while simplistic hand cranks adjust the Videojet 9550 up and down for product height.

Super sanitary designs include slotted clean out ports; welded stand-offs for guide rail brackets, bearings, and floor supports; welded internal frame spacers; removable wear strips; and continuous welds - all ground and polished, in this case, for 3A Dairy approval.

To see Multi-Conveyor's machine in operation, click here.